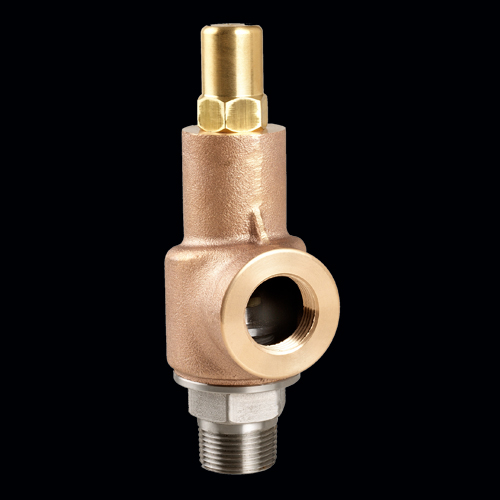

TAYLOR VALVE PRODUCTS

High quality U.S. manufactured valves designed to meet many options encountered in the oil and gas industry. Where to BuyBrass Series

The Taylor Brass Series Valves are designed for Liquid Relief by-pass, Air/Gas Protection and High Pressure applications making them an excellent choice for Air, Gas or Liquid relief applications.

Features

69 Series

• Field adjustable by simple removal of the hex-cap

• Metal to metal precision lapped seating

• Back pressure tested

• Ease of cleaning and maintenance with simple bonnet removal.

• Stainless steel springs

• Single piece – 100% leak free bonnet Features:

88/89 Series

• Precision lapped metal to metal seating

• Stainless steel springs

• Ruggedly constructed

• Closed seal hex cap or lift lever options

• Wide variety of inlet and outlet options

• Disk-guided seat provides quick, accurate and excellent re-seating

• Maximum temperature 406°F (208°C)

560/570 Series

• Designed for durability

• 6 orifices – 12 sizes of piping options

• Top guided seating and discharge

• Full nozzle, high-capacity levels

• Short, tuned blow-down with dual-ring technology

• Heavy duty hood and lever mechanism

• Standard 17-7 stainless steel springs

Applications

69Series:

- Include liquid by-pass, regulation, continuous relief and over-protection. Used on pumping stations, tanks, hydraulics, fluid / piping lines, oil fields, gas lines and more where a Liquid or Water Relief Valve is needed

88/89 Series:

- Over pressure protection on Pressure vessels, Piping systems, Tanks, Compressors, Dryers, Inter and After-coolers

560/570 Series:

- Steam Boilers, Air Compressors, Dryers, Receivers, Pressure Vessels, Piping Systems, Accumulators, Reducing Stations, Tanks, Inter/AfterCoolers, Cooking Equipment, Autoclaves, Sterilizers or wherever higher-capacity pressure protection or relief may be required