TAYLOR VALVE PRODUCTS

High quality U.S. manufactured valves designed to meet many options encountered in the oil and gas industry. Where to BuyRB Control Choke Valves

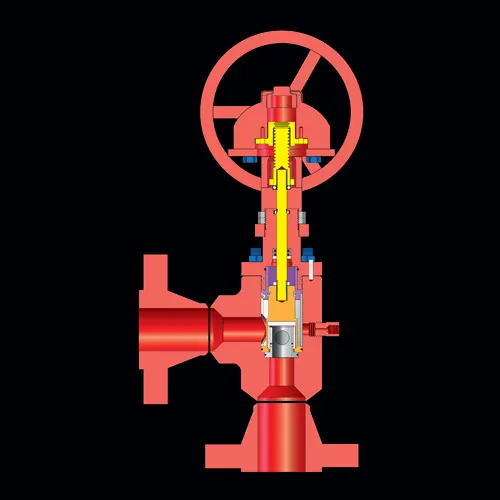

The RB Series: RB Control Choke Valves’ unique valve trim design provides accurate control by the use of precision orifices in the flow nozzle. This design minimizes wear and maximizes service life.

Specifications

Connection Size: 2″, 3″, 4″, 6″

Connection Type: Flanged

Body Style: Angled

Body Material: LACS 4130

RB2 Control Choke Valve

Cv: 3, 6, 12, 35 (Standard)

Bean Size: 78 / 64th’s (Standard)

Stroke Length: 1.25”

Stem Diameter: 0.625”

MAWP: 10,000 PSIG

HU MAWP:15,000 PSIG

RB3 Control Choke Valve

Cv: 35, 64, 78, 95, 115 (Standard)

Max Bean Size: 141/64ths

Stroke Length: 1.75”

Stem Diameter: 0.625”

MAWP: 6,000/10,000 PSIG

HU MAWP:10,000 PSIG

RB4 Control Choke Valve

Cv: 80, 164

Bean Size: 169 / 64th’s

Stroke Length: 2.45”

Stem Diameter: 0.75”

MAWP: 6,000/10,000 PSIG

RB6 Control Choke Valve

Cv: 78, 420

Bean Size: 270 / 64th’s

Stroke Length: 4.25”

Stem Diameter: 1.0”

MAWP: 6,000 PSIG

Applications

- Well Site Automated and Manual Application

- Water Injection Control Valve

- CO2 Injection Control Valve

- High Pressure Drop Applications

- Gas Lift Injection Control

Actuator Options

This Choke can be fitted with actuator options to provide accurate pressure relief performance.

Features & Benefits

The RB Series Control Valve features several unique design characteristics that minimize wear and maximize service life. The nozzle and external sleeve trim is designed to contain turbulence and wear by managing the flow into the nozzle and centralizing it into bore causing the flow streams to impinge on each other. The valve body and outlet are protected from wear because the energy conversion as a result of the pressure drop is concentrated in the trim cavity before the flow enters the outlet. This eliminates the typical wear problems in the valve outlet. The Upstream and Downstream balanced sleeve design greatly reduce the breakway and closing thrust requirements to lift the sleeve on and off seat as well as during stem travel making the control stable and precise yielding better accuracy and repeatability.

Additional Benefits

- Accurate Control – Multi-Orifice Nozzle design provides precise control over a wide range of flows.

- Bolted Bonnet – A bolted bonnet prevents corrosion, cross-threading, and galling of large threaded connections. The design allows for simple assembly and disassembly.

- Extended Mean Time Between Service – Robust design, application of hardened materials, and efficient flow geometry results in maximum production potential and minimum service requirements.

- Easy Maintenance – All Control Choke Valves are designed with special actuator mounting systems so the choke can be maintained without disassembly of the actuator and components or instrument connections.

- High Turndown Ratio – Clean flow geometry, high capacity, and accurate control mean the valve is suitable for both start-up and end-of-field-life-process scenarios. In short, our control choke valves offer a one-valve solution for the full process life.

Optional Features

Control Valves can have trims and actuators custom-designed for specific requirements. Such as special noise reduction trims, reduced port, and maximum orifice trims for very high pressure or minimum pressure loss for a declining field.